- T.01323 844841

- E.sales@mgpsteel.co.uk

- T.01323 844841

- F.not available

- E.sales@mgpsteel.co.uk

Projects

Some projects recently completed in the South of England include:

EHA Derrys, Plymouth

currently working in close coordination with EHA Developments to supply and install nearly 1000 tons of refurbishment and structural steelwork.

The brief of this redevelopment project is essentially to turn a derelict 1950’s / 1960’s department store, into a vibrant 22,000 M² mixture of Student accomodation, Premier Inn, commercial and retail space.

The work is a mixture of multi-storey new steel installed on top of and adjacent to existing with large scale refurbishment steelwork installed to create a series of courtyards to utilise natural light.

Alongside the usual logistical challenges presented by such a large city centre development, some of the steelwork highlights include:-

a 35 metre long, nearly 2 storey high truss to be installed over an existing live retail unit

seamlessly adding and integrating 4 new storeys of steelwork to an existing 5 storey structure

Read more of Plymouth Herald’s front page story here

and check out a cool quick video here 2min vid

Buxtons Building Contractors – Malthouse

MGP, working closely with Buxton building contractors and to exacting architectural and engineering specifications and requirements, helped to turn a semi-derelict Victorian Malthouse, into a state of the art modern theatre and performing arts centre.

To ensure the nearly 90 ton of fabricated steel supplied interfaced seamlessly with the existing timber and cast iron structure, many days were spent on site surveying with our state of the art Leica total station which generated one of our biggest point clouds to date.

The steelwork was installed predominately by hand using a huge range of specialist equipment alongside plenty of muscle and determination on behalf of the erection crews.

Adding to the usual challenges, the stringent architectural expectations meant that exposed steel, whilst serving it’s structural purpose, also had to look ‘Victorian’ hence the multiple bolted connections with architectural bolt alignment preferred to welded connections.

As the project progressed MGP’s experiences and skill set would be tested, including the repair of 16No. Victorian structural cast beams, damaged during demolition and the installation by hand of 16M x 1M x ¾T Vierendeel trusses to support the walkways and lighting rigs.

As usual MGP rose to and overcame all the challenges presented to us.

Bayswater

MGP Steel Erection Limited, working closely with their colleagues at Southdown Truck and Crane and using all 17m of their Rigid 8×2 Hiab c/w 80 t/m HIAB 800 Hipro, threaded 7 tonnes of fabricated steel, from a busy London Street, across a pavement, through a shop and then down into the basement.

The steel was then installed by hand in the basement to enable our clients Resolution Interiors to strengthen the building to facilitate it’s conversion into the latest Urban Screwfix Store – All on a tight schedule to the complete satisfaction of our clients.

Railway Buildings

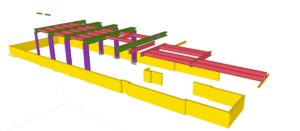

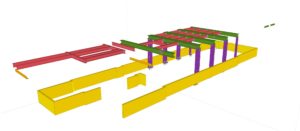

The latest Railway Transformer and Plant Shelter Building as recently completed on time and to the complete satisfaction of MGP’s client Atkins Rail and everybody else associated with the project.

Over the last 4-5 years MGP have supplied and installed nearly 50 no. similar Steel Frame Buildings at multiple Network Rail sites throughout London and the South-East working for many different contractors to the complete satisfaction of all parties concerned. During the period we have been working on the railways our teams have gained a wealth of experience of overcoming the challenges of working Railside including isolated and island sites.

The building at Selmeston was unique in that it was manufactured to a higher level of specification and finish with the introduction of Louvre Panels for Venting and the addition of demountable roof system for ease of access with regards the plant contained within.

John Street Police Station, Brighton

MGP accepted Morgan Sindall’s challenge of building an eight storey free standing steel structure bounded and confined by an existing and busy police station to three elevations, with a road to the fourth side within the centre of Brighton. As if this wasn’t enough of a challenge the structure also had to punch through a lightweight concrete slab to connect to the foundations a further storey down. With regards access, MGP utilised lightweight and Compact Cherry Pickers and Scissors Lifts that had just enough duties to safely reach the top of the steel and were just slim enough to squeeze in amongst the densely packed steelwork – Nearly 30 no. Columns were crammed into just over 170m2. The steelwork design presented all sorts of challenges for the MGP detailing team but using the Tekla 3D modelling software these were overcome. We were not quite done – Working with Morgan Sindall and Stannah a further 6t steel was introduced and detailed to support Lift Shaft Track rails and to provide an Anti-Fall Through Screen between the 2 no. Lift Shafts.

Nearly 6 months after MGP issued their initial Drawings we have detailed 5000 Fittings and 1,600 Shafts to form approx. 1,500 no. Steel Assemblies weighing nearly 150t. Following fabrication this steel was painted with 500 litres of primer paint and then installed using nearly 8,000 bolts. Despite all the challenges, MGP are confident that we have successfully provided a multi storey steel frame that meets all expectations and specifications to the satisfaction of all parties involved.

Holland Park

MGP supplied 30 tonnes of steel in 2500 pieces to create a 2 winged 25 metre unique advertising structure. Following the erection of the structure the client decided to rotate the sign a number of degrees to increase their revenue, MGP used 2 cranes to lift the complete structure then slid a 2 ton plate beneath it to re-affix the rotated structure achieving the desired result.

Gardners Books

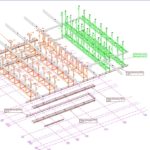

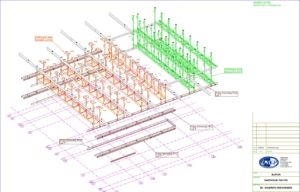

MGP worked with developer and specialist cladding contractor LCS to supply and install large structural cold rolled steel frame to house a cutting edge Hi-bay robotic storage and distribution facility.

The new facility was formed of five interlinked buildings that in turn required to integrate seamlessly with the existing structure.

In total there was nearly 500 tonnes of structural steel and 8 km of cold rolled, the highest columns were 16 metres tall and to create a versatile loading bay area a single 25 metre span was created using 1 metre deep beams.

All the above work was undertaken against the ticking clock of the Hi-Tech conveyor system being delivered from the Far East.

click these links for time-lapse videos of the project in action video 1 video 2

Bexhill High Academy

MGP Steel Erection Ltd, were contracted to install a two storey, infill steel structure, constructed from 40ton of structural steel and 2000metres of cold rolled floor beams, within an existing school.

The works had to be completed within a two and a half week period, with every element of the build, materials and access equipment passing through the double doors at the front of the existing building.

This job was proudly finished early, to the immense satisfaction of the client

click here to view a timelapse video of the complete install

MX Start Gates

5

As well as structural steel MGP Steel Erection Limited also manufacture MX Start gates for many clubs and circuits around the British Isles, well designed and heavily galvanised for a long life, call or email us with your requirements.

Old Street

We were contracted to undertake the refurbishment and redevelopment of an existing sign structure located on a very busy roundabout above an underground station in central London we deconstructed and removed all of the redundant steelwork, mostly at night, replacing it with a new structure including walkways and gantrys with trimming and weather proofing for the protection of the four 4metre x 12metre digital screens now suspended by macalloys a new London landmark, featured in the Evening Standard.

Contact us

Tel01323 844841

Emailsales@mgpsteel.co.uk

MGP Steel Erection Ltd

European House

Hackhurst Lane

Hailsham

East Sussex

BN27 4BW

Copyright 2025